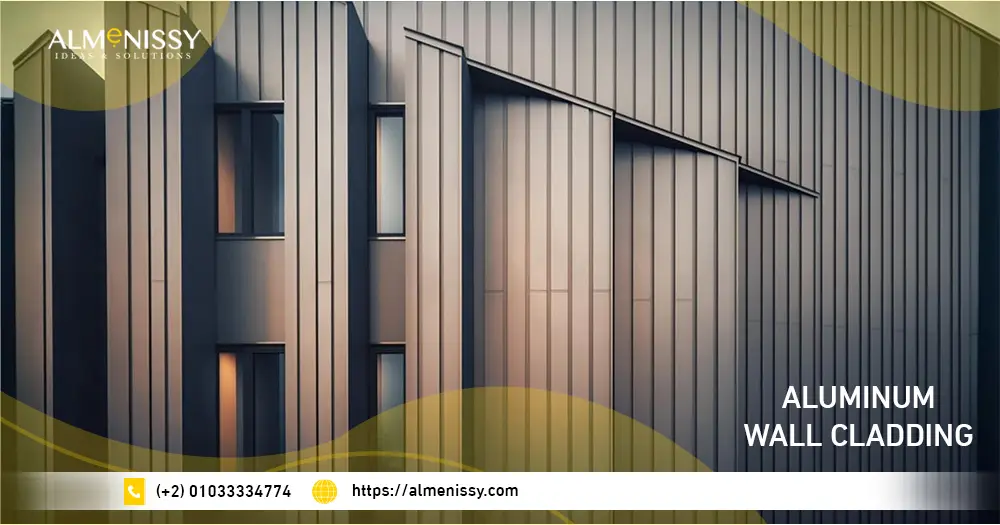

Aluminum wall cladding is a modern solution that combines beauty and functionality in the world of construction and design. With the increasing importance of exterior design of buildings, aluminum has become a popular choice thanks to its lightness, durability, and resistance to weather factors.

This technology allows engineers and architects to create stunning facades that combine elegance and modernity, reflecting the identity of the place in a distinctive way. Aluminum wall cladding is used in a variety of projects, from commercial buildings to residential villas,

adding a modern touch to the design.

Table of Contents

What Is Aluminum Wall Cladding?

Aluminum wall cladding is a modern technology used to cover the exterior walls of buildings with panels made of aluminum, which contributes to improving the aesthetics and functionality of the building. These panels can withstand various weather factors such as wind and rain without being affected.

In addition, aluminum is resistant to corrosion, making it an ideal choice for humid or coastal environments. This technology also provides effective thermal and sound insulation, which contributes to improving energy efficiency within buildings.

How Is Aluminum Cladding Installed?

1. Planning And Designing:

- Determine the desired design and choose the appropriate panels.

- Accurately measure the walls to determine the amount of aluminum required.

2. Surface Preparation:

- Clean the walls from dirt and debris.

- Repair any defects in the base wall to ensure a level installation.

3. Frame Preparation:

- Install an iron or aluminum support frame on the walls.

- Ensure that the frame is level and stable to facilitate the installation of the panels.

4. Installing The Panels:

- Start installing the panels from the bottom up.

- Use clamps or nails to hold the panels in place.

5. Checking Alignment:

- Ensure that the panels are properly aligned and fit the specified design.

- Adjust any panels that are not straight before installing them completely.

6. Sealing Gaps:

- Fill any gaps between panels using fillers or sealants.

- Ensure that the cladding is tight to prevent water leakage.

7. Final Finishing:

- Add decorative elements or accessories if necessary.

- Clean the surface and remove any installation residue.

8. Final Review:

- Inspect the completed work.to ensure the quality of the installation and ensure that there are no defects.

- Prepare a report on the installation and submit it to the client.

What Is The Purpose Of Aluminum Cladding?

The purpose of aluminum wall cladding revolves around improving the aesthetic and functional performance of buildings. Aluminum wall cladding is an effective way to protect buildings from weather factors such as rain, wind, and snow, which contributes to increasing their durability and longevity.

This technology also provides thermal and sound insulation, which enhances the energy efficiency of buildings and creates a comfortable environment for residents. In addition, aluminum wall cladding allows designers and engineers the opportunity to add a modern and aesthetic touch to facades, as the panels are available in a variety of colors and finishes that suit different architectural styles.

What Are The Different Types Of Aluminum Cladding?

Aluminum wall cladding comes in several types, varying in design, use, and characteristics. Here are a few of the most common kinds:

1. Aluminum Composite Panels (ACM):

- Consists of two layers of aluminum with an inner material, providing strength and durability with a light weight.

- They are often used in the facades of commercial buildings and shopping malls.

2. Painted Aluminum Panels:

- Feature an external coating that can be customized in different colors.

- They are used for a variety of purposes including interior and exterior cladding.

3. Anodized Aluminum Panels:

- They undergo an electro-oxidation process that increases corrosion resistance and provides an aesthetic touch.

- They are used in applications that require a beautiful appearance with strong performance.

4. Perforated Aluminum Panels:

- They contain small holes that allow light and air to pass through, giving an artistic and modern appearance.

- Used in innovative architectural designs and to improve ventilation.

5. Cold-Rolled Aluminum Cladding:

- It is used in applications that require precision in shape and design.

6. Customizable Panels:

- Can be custom designed to meet specific needs in architectural projects.

- Provides flexible and innovative design options.

What Is The Lifespan Of Aluminum Cladding?

The lifespan of aluminum wall cladding depends on several factors, including the quality of the materials used, installation methods, and the surrounding environmental conditions. In general, aluminum cladding can last between 20 to 50 years, or even longer in some cases. Aluminum is a corrosion-resistant material.

Which gives it a significant advantage over other materials. However, environmental factors such as humidity, direct exposure to ultraviolet rays, and pollution affect its durability. If aluminum cladding is maintained regularly and proper maintenance procedures are followed, its lifespan can be significantly increased.

Is Aluminum Cladding Waterproof?

Yes, aluminum cladding is considered waterproof, making it an ideal choice for use in humid and weather-prone environments. Aluminum itself is a natural material that does not absorb water, and has corrosion-resistant properties, which prevents the development of rust or damage due to exposure to moisture.

However, the effectiveness of aluminum cladding’s waterproofing also depends on the quality of the installation and the materials used in the installation process. It is essential to ensure that the gaps are properly sealed and that sealants are used during installation to ensure that water does not seep into the structure.

Conclusion

In conclusion, it is clear that aluminum wall cladding represents an ideal choice that combines beauty and functionality. Its ability to withstand weather conditions, while providing effective thermal and sound insulation, makes it suitable for various types of architectural projects. The variety of colors and finishes also gives designers and owners the opportunity to express their vision and give a unique character to buildings.

Moreover, the easy maintenance of aluminum elements increases their appeal, making them a long-term investment. According to Alminssy Company, aluminum wall cladding remains a leading option that meets the needs of the present and the future. Therefore, if you are thinking of improving the facade of your building or project, aluminum cladding is worth considering as a strong and effective option.

FAQ

Does Aluminum Cladding Get Hot?

Yes, aluminum cladding can get hot when exposed to direct sunlight, as aluminum is a good conductor of heat. However, aluminum panels often come with thermal insulation technologies.

Is Aluminum Good For Cladding?

Yes, aluminum is an excellent material for cladding due to its durability and resistance to corrosion and weathering. It is also lightweight, easy to install, and offers a variety of design options in terms of colors and finishes.